IBM Cloud, Blockchain, S2CT's Global Asset Management Architecture and Ubiquitous Wi-Fi Render GPS and Digital Cellular Networks Communications Obsolete in the Global Supply Chain

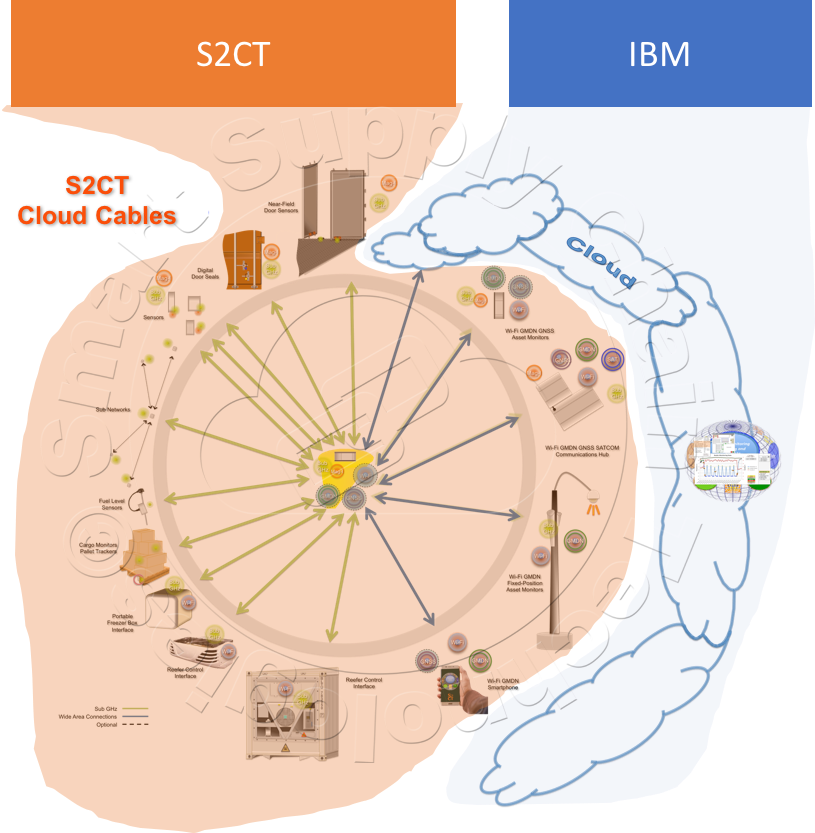

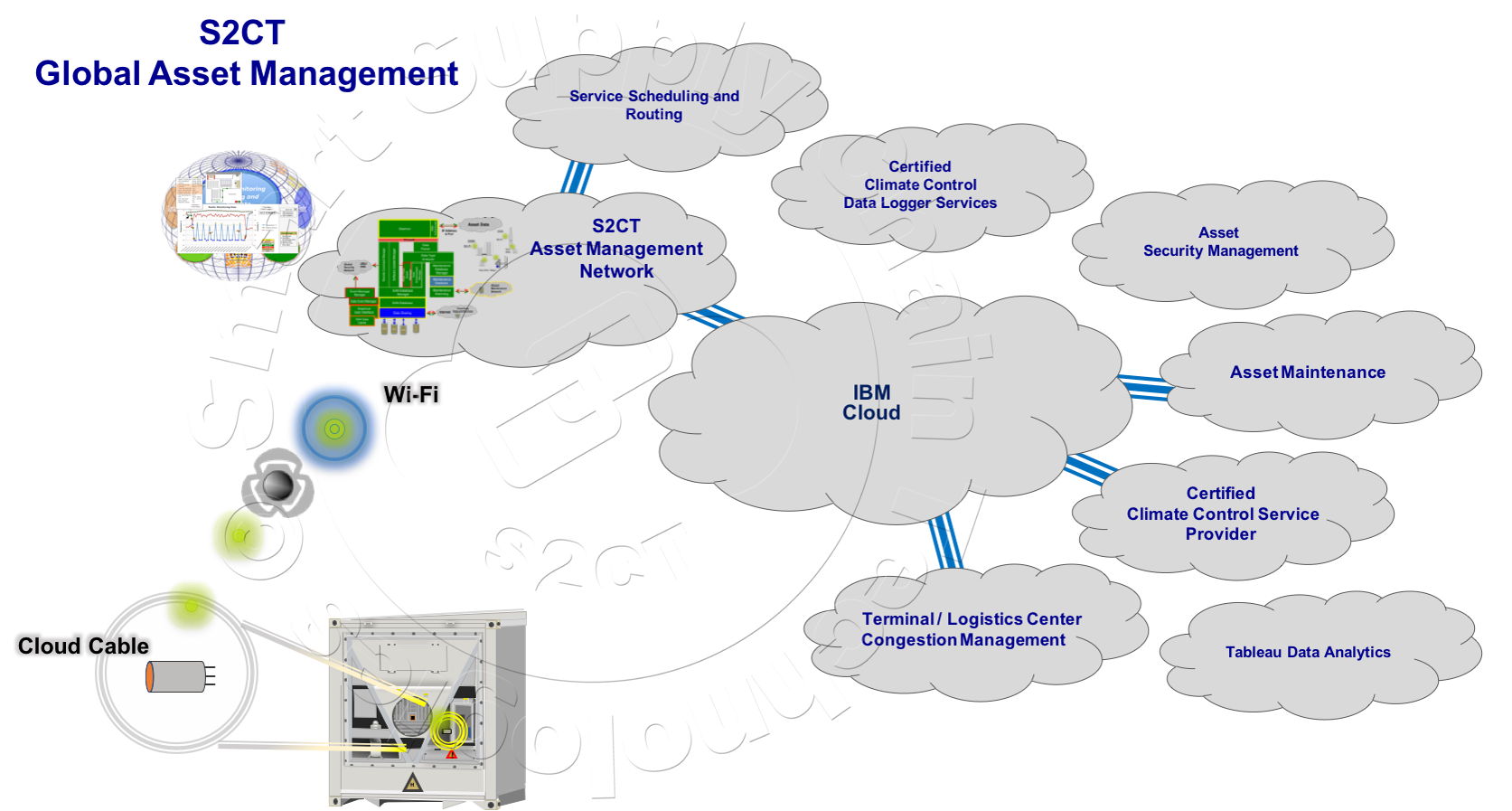

IBM's Cloud, hosting S2CT's Asset Management Network using Watson Analytics and Blockchain technology, and S2CT's Wi-Fi Cloud Cables change everything for supply chain asset management. The IBM Cloud and "Watson", IBM's Supercomputer, are everywhere, using Blockchain technology and the most sophisticated data analytics available to pinpoint the locations of assets anywhere on the planet: in terminals, freight yards, and depots, on the road, rail, and sea or even in the air, just using data available in the cloud.

IBM's Cloud, hosting S2CT's Asset Management Network using Watson Analytics and Blockchain technology, and S2CT's Wi-Fi Cloud Cables change everything for supply chain asset management. The IBM Cloud and "Watson", IBM's Supercomputer, are everywhere, using Blockchain technology and the most sophisticated data analytics available to pinpoint the locations of assets anywhere on the planet: in terminals, freight yards, and depots, on the road, rail, and sea or even in the air, just using data available in the cloud.

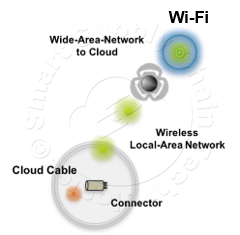

The IBM Cloud and S2CT Wi-Fi Cloud Cables are a game changer, tying it all together and making the S2CT's Asset Management Network available everywhere! The S2CT's Cloud Cable can be plugged into the I/O port on any piece of equipment to tie it to the Internet through an available Wi-Fi Access Point. Think of the Cloud Cable simply as a "cable" that connects two points together without the physical cable, "wirelessly".

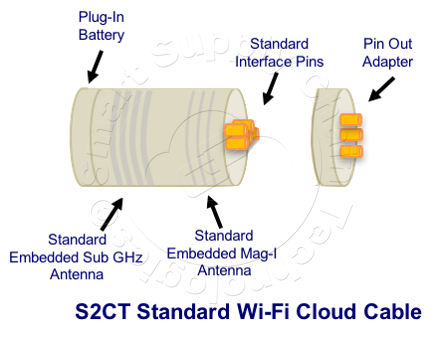

All S2CT's Cloud Cables are programmable microcontroller based, have plug-in Battery Power Systems, integrated Sub GHz(1) subsystems with an embedded Sub GHz antenna, integrated Magnetic Inductance (Mag-I) with an embedded Near Field Mag-I antenna, a standard set of six programmable Input / Output pins, 8Kbytes SRAM Data Logger (64 pings).  The Battery Power System can house up to 3 AA batteries with "Smart" Advanced Power Management for extended life. Standard I/O adapters are available for USB, Serial, and UART data plugs. Standard Cloud Cables, intended to communicate through Sub GHz to Sub GHz enabled Wi-Fi APs, will sell for around $25 USD. A single Sub GHz enabled Wi-Fi AP can provide network communications to hundreds of Standard Cloud Cables in its field of coverage. Wi-Fi enabled Cloud Cables that can communicate directly with standard Wi-Fi APs are also available.

The Battery Power System can house up to 3 AA batteries with "Smart" Advanced Power Management for extended life. Standard I/O adapters are available for USB, Serial, and UART data plugs. Standard Cloud Cables, intended to communicate through Sub GHz to Sub GHz enabled Wi-Fi APs, will sell for around $25 USD. A single Sub GHz enabled Wi-Fi AP can provide network communications to hundreds of Standard Cloud Cables in its field of coverage. Wi-Fi enabled Cloud Cables that can communicate directly with standard Wi-Fi APs are also available.

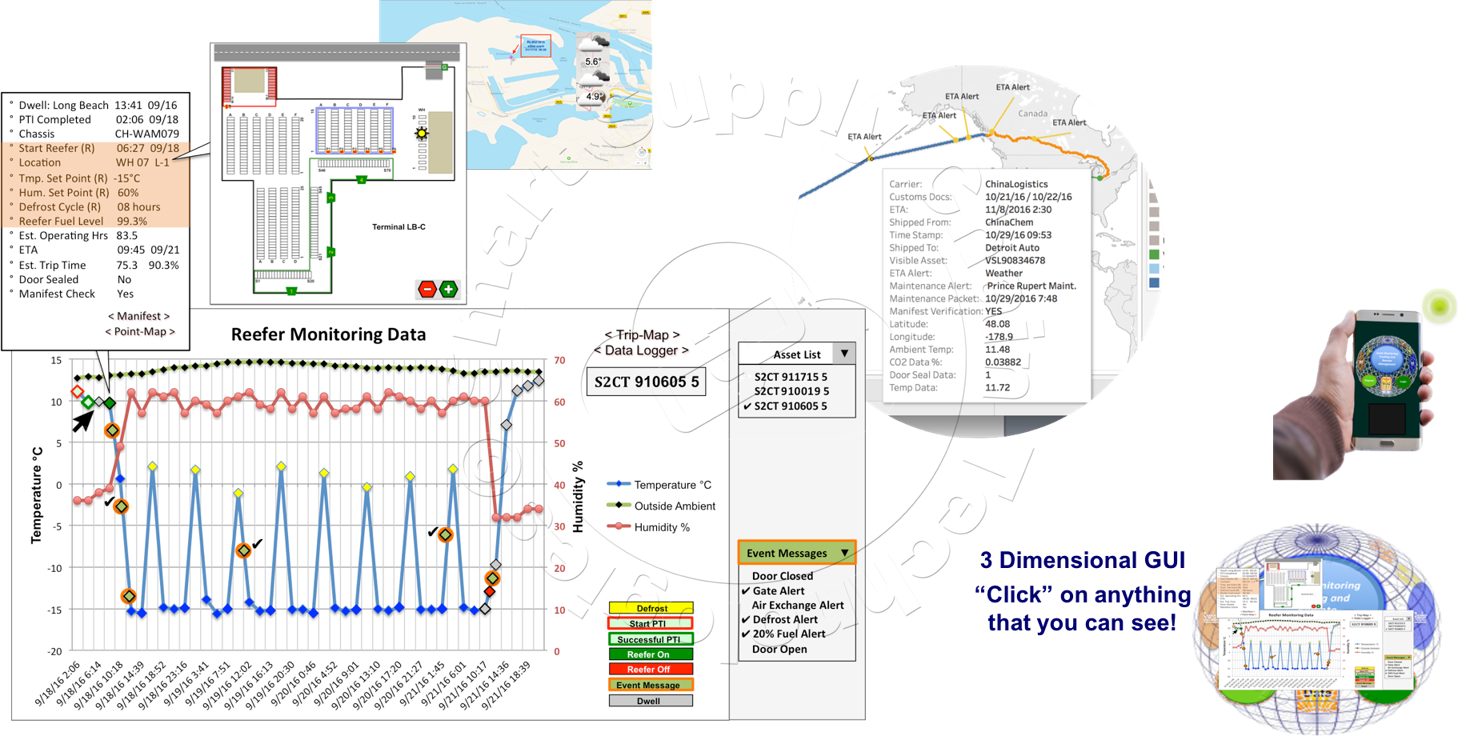

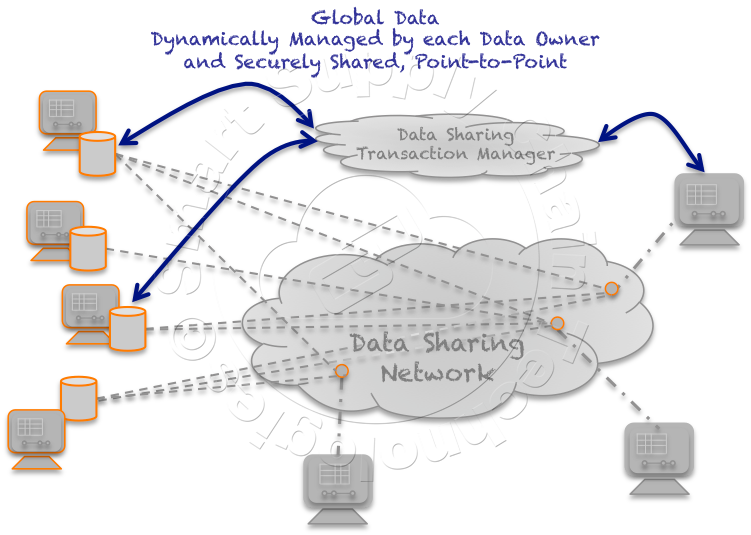

S2CT's Asset Management Network, in the IBM Cloud, does the rest. The S2CT's Asset Management Network receives data from Cloud Cables, analyzes it discretely and with other data, in many cases using Watson, and stores it all in an Asset Monitoring Database. In some cases, the Asset Management System passes and shares(2) data to other Cloud Service Providers. The "Blue" lines connecting the cloud services below are those that were used in our Caviar journey, Service Scheduling and Routing, Asset Maintenance, Certified Climate Control Services and Terminal / Logistics Center Congestion Management. Each of these cloud service providers hosts their own software, analytics, and databases.

Many asset management solution providers mistakenly rely on GPS or other Global Navigation Satellite Systems to track and locate assets operating in the global supply chain. Virtually all of these companies are held captive by their own earlier investments in those technologies or don't actually realize asset monitoring is not real-time navigation. Many of their potential customers do and have demonstrated that by their reluctance to pay for expensive devices using this underlying technology and its associated real-time broadband communications: GSM, 3G, 4G, etc. These technologies drive the cost and therefore the price of asset monitoring devices higher through the cost of their hardware components, modules and antennas, and the additional batteries required to support them. Worse yet is the added recurring monthly cost of paying for real-time Telco data services, which goes on for the life of the asset.

S2CT's Cloud with Watson, using Blockchain-of-Custody and other data available in the cloud, coupled with periodic Wi-Fi location markers(3), accurately estimates the geospatial position of assets anywhere in the world, without all the overhead. Moreover, Watson, using advanced analytics, can provide "precision" 3-axis geospatial position of assets, with centimeter accuracies, when they are within the Wi-Fi bubbles of shipping terminals, freight yards, and similar facilities, using Wi-Fi and Sub GHz triangulation algorithms. Precision at the places where knowing the "precise" position of an asset has "real" value and where Wi-Fi networks are nearly ubiquitous.

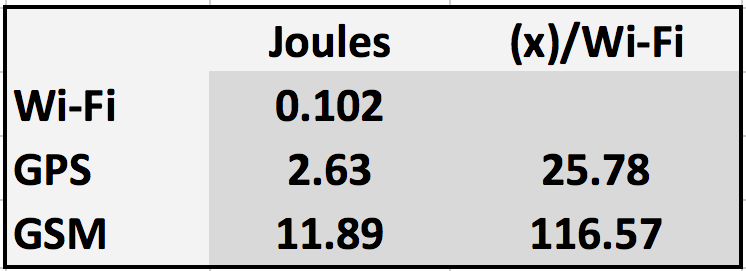

By comparison, Wi-Fi power consumption is about 1/10th of that used by GPS(4) for a typical non-persistent connection and as much as 1/100th when connecting within a persistent Wi-Fi bubble. GainSpan and RF Digital announced, in mid-2008, a Wi-Fi module capable of a ten-year battery life, from a single Alkaline AA battery(5), for a device continuously communicating with a persistent Wi-Fi connection. Mobile asset monitoring devices have little choice but to be designed to operate exclusively on battery power for autonomy, and long battery life is essential. Years of operation without battery maintenance is the industry benchmark. To that end, GPS / GSM based asset monitoring devices are typically designed to house between 10 to 15, high-capacity, Lithium-Ion type batteries. Wi-Fi based devices, requiring 1/10th of the power from their batteries, require 1/10th the number of batteries, one battery instead of ten. Not to mention the cost of dealing with the hazardous(6) Lithium-Ion battery chemistry, recently showcased by Samsung, Lithium-Ion batteries are two to three times the cost of Alkaline batteries. A Wi-Fi based asset monitoring device operating on two Alkaline batteries would reduce the device battery "cost" by more than 90%, by $30 to $40 USD. S2CT's advanced machine-learning power management optimizes the cost to performance ratio and battery life of mobile asset monitoring devices.

Now, for Wi-Fi versus GSM/GPRS. Obviously, connecting supply chain mobile assets to the Internet and the IBM Cloud and Watson requires a reliable wireless connection to a communications network capable of reaching the Internet. This is another area where asset management solution providers have misunderstood what their perspective supply chain customers actually require, for many of the same reasons surrounding their continued use of GPS. Major electronic component providers, like Telit, provide combination GPS / GSM modules to the expanding navigation and communications automotive and smartphone markets. Those markets make those modules, and the related Telco data services, readily available to supply chain asset management providers, but at a cost to their customers.

Reliable in the aforementioned context, means that an asset monitoring device can connect to a communications network anywhere it travels in the global supply chain. Asset Management Solution providers are already struggling with 2G (GSM), 3G and 4G communications infrastructure issues around the world as 2G is fast coming to its end-of-life. There are a number of countries today, that play important roles in the global supply chain, that no longer offer connections for 2G (GSM) devices, this trend will continue. Many countries are even choosing to skip 3G infrastructure buildouts to go directly to higher speed 4G networks to protect their investments. 5G broadband research is already well underway, again driven by real-time applications delivering video and similar content to consumers. High-speed real-time broadband communications adds no value to the relatively small data / long latency communications required to monitor supply chain assets. By comparison, Wi-Fi 802.11(x) is stable and offers compatibility around the world! S2CT's expertise in wireless communications and antenna theory ensures reliable and secure Cloud Cable connections to Wi-Fi networks anywhere these assets travel in the global supply chain.

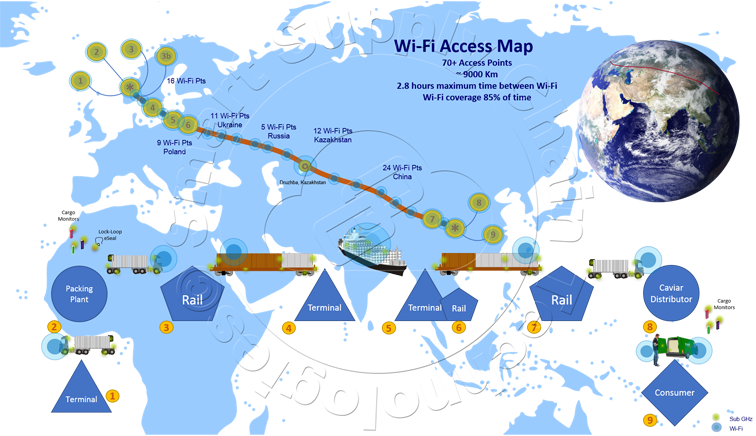

Clearly, broadband mobile communications like GSM, "can" be used for communicating with supply chain mobile assets but as laid out here, at a significant cost. Supply chain mobile asset monitoring requires "real-time data" but very seldom does it require "real-time communications". Knowing when and where an actionable-asset-event occurred, when the asset is moving between terminals, within a few hours of an event is more than adequate 99% of the time. Typical events that happen between terminals and yards are not realistically actionable until the asset arrives in a terminal or yard or until someone is dispatched to intercept the asset. Beyond that fact, 98% of all actionable-asset-events occur when the asset is in a terminal or yard and within a Wi-Fi bubble where it can be communicated and actioned in real-time. Virtually every shipping / rail / truck / air / freight terminal in the world has an available Wi-Fi network. Figure 1 illustrates Wi-Fi network access across the New Silk Road, from Western Norway, across Eastern Europe, to Ji'an, China.

Finally, Blockchain, developed to track the changing ownership of alternative currencies through secure ledger entries, is seamlessly applicable to tracking the dynamic change-of-custody of assets, cargoes, trailers, containers, etc. This simple, yet effective and secure technology, can track the change-of-custody of cargo across its supply chain journey, from factory to customer and through all the points. Of course, Reefer Blockchain-of-Custody tracking also tracks the cargo in the Reefer without exposing the deeper asset and cargo data. IBM's Cloud hosting S2CT's Asset Management Solution, securely provides and dynamically manages this deeper asset data and its sharing for each of its users and their dynamic supply chain business partners and stakeholders.

An easy way to appreciate the effectiveness of these technologies is to take a close look at a journey through the global supply chain using a simple "Cloud Cable", from one of S2CT's partners, and S2CT's Asset Management Network hosted on IBM's Cloud with Watson. A Cloud Cable is an inexpensive Sub GHz wireless device, that wirelessly connects two devices together. A Cloud Cable might be plugged into the I/O port of a reefer's controller, as illustrated in our journey, to connect it wirelessly to Wi-Fi Access Points and the Internet.

An easy way to appreciate the effectiveness of these technologies is to take a close look at a journey through the global supply chain using a simple "Cloud Cable", from one of S2CT's partners, and S2CT's Asset Management Network hosted on IBM's Cloud with Watson. A Cloud Cable is an inexpensive Sub GHz wireless device, that wirelessly connects two devices together. A Cloud Cable might be plugged into the I/O port of a reefer's controller, as illustrated in our journey, to connect it wirelessly to Wi-Fi Access Points and the Internet.

We will follow a shipment of chilled caviar from a Norwegian Fish Market in Bergen, Norway, to a high-end restaurant in Ji'an, China. The journey begins when the Norwegian Fish Market awards a contract to a Norwegian Logistics Company, using its S2CT's Asset Management Network to manage the transport of its product to China, on the basis of the shipping cost, the ability to monitor and manage the product's care and its arrive-by-time commitment. The Norwegian Logistics Company's price reflects its discounted cost of insurance based on the basis of its ability to monitor and remotely manage the customer's cargo and its asset throughout its journey, including with collaborating carriers. The Norwegian Logistics Company's arrive-by-time commitment reflects its fast path through Border Crossings and Customs, and Check Points along its route, with its Green Lane(7) Designation. Watson's continuous management of the Reefer into and out of terminals to avoid congestion delays can also save as much as a full day in this journey. Genset Power Management, by the Certified Climate Control Services Provider, can increase a Reefer generator's fuel efficiency by as much as 25%. The Fish Market also qualifies for a discounted cargo insurance premium based on its ability to monitor its cargo from the data shared by the Norwegian Logistics Company, including the Reefer Controller's Data Log data when requested.

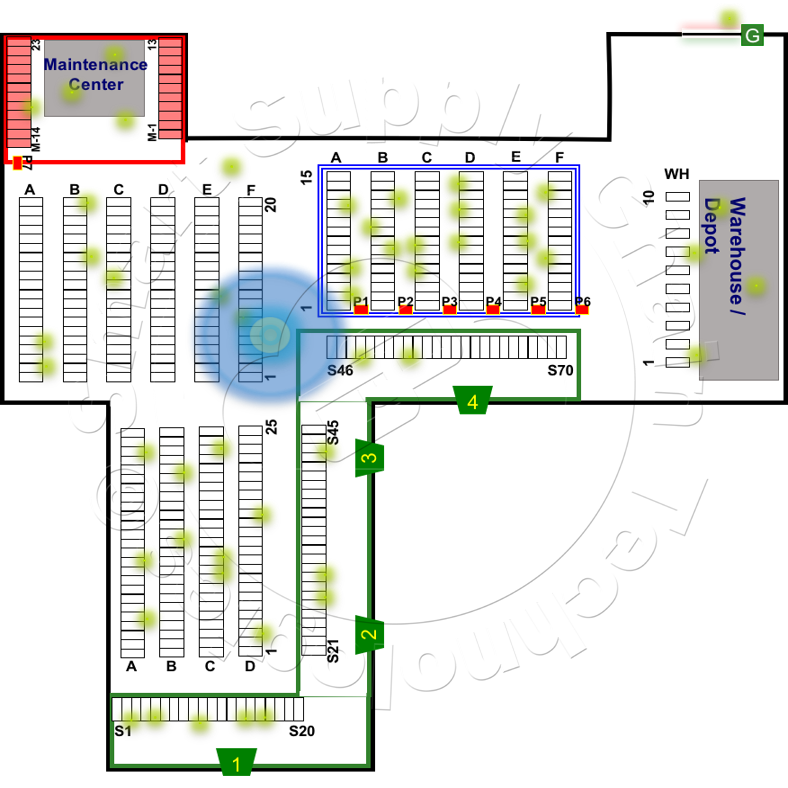

① Norwegian Logistic Company's Terminal

① Norwegian Logistic Company's Terminal

The Logistics Company agrees to provide a "cloud-managed", secure, autonomous refrigerated container, with Certified Climate Control Services. The Logistics Company agrees to share change-of-custody and drill-down data with the Fish Market and to allow the Fish Market to share selected data with its end-customer.

The Logistics Company provides the Fish Market with an Estimated Time of Arrival (ETA) for its container to arrive at its loading dock, projected by Watson based on available equipment and personnel, the time of day, weather and traffic conditions. The Logistics Company uses S2CT's Asset Management System to project the container's route from its terminal to the Fish Market, estimate the time required to load the Fish Company's cargo, and estimates the container's ETA at the local railway terminal for transfer onto a railroad car. The Asset Management System allocates a specific Reefer, a truck cab, and a chassis that support the customer's shipping and monitoring requirements. Watson will continuously analyze the Reefer's progress as it makes its way through its journey, including changing route conditions, to weigh impacts on its projected ETAs and update effected destinations as required.

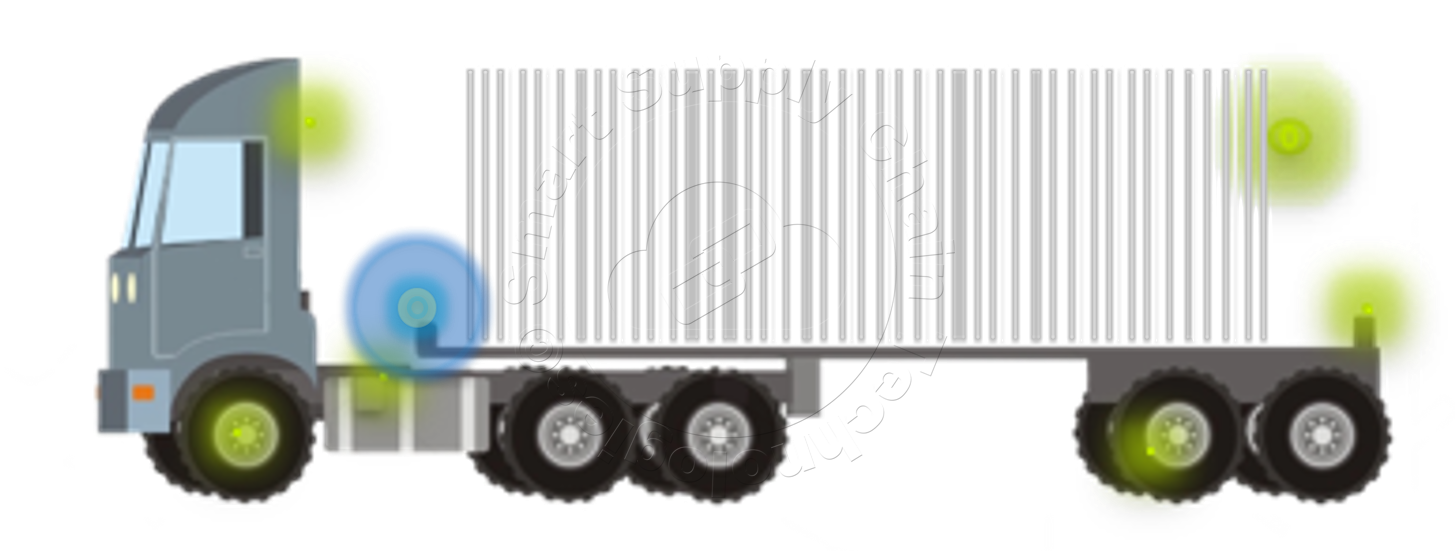

The Logistics Company's S2CT Asset Management System selects and locates a "connected" chassis from its inventory, equipped with a Wi-Fi enabled Cloud Cable, Tire Pressure and Light Sensors, axel sensors and a "Ready" Status with a "Good" rated maintenance record and history adequate for the "local" Fish Market assignment.

The Logistics Company's S2CT Asset Management System selects and locates a "connected" chassis from its inventory, equipped with a Wi-Fi enabled Cloud Cable, Tire Pressure and Light Sensors, axel sensors and a "Ready" Status with a "Good" rated maintenance record and history adequate for the "local" Fish Market assignment.

The Logistics Company's S2CT Asset Management System selects and locates a "connected" chassis truck cab from its inventory, equipped with a Cloud Cable, Tire Pressure and Light Sensors, a Fuel Level Sensor, a ODM-II / CAN Interface, a "Ready" status with a "Good" rated maintenance record and history adequate for the "local" Fish Market assignment.

The Logistics Company's S2CT Asset Management System selects and locates a "connected" chassis truck cab from its inventory, equipped with a Cloud Cable, Tire Pressure and Light Sensors, a Fuel Level Sensor, a ODM-II / CAN Interface, a "Ready" status with a "Good" rated maintenance record and history adequate for the "local" Fish Market assignment.

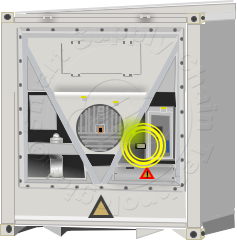

The Logistics Company's S2CT Asset Management System selects and locates a Green Lane compliant, "connected" Autonomous Refrigerated Container from its inventory, equipped with a Cloud Cable Reefer Controller Interface, a Power-Managed Diesel Powered Generator with a Cloud Cable Genset Controller interface and Fuel Level and Fuel Cap Open Sensors, in "Ready" Status (Clean and Passed Pre-Trip Inspection) and with a "Very Good" rated maintenance record and history adequate for the "long-haul" Fish Market assignment and compatible with cargo monitoring requirements specified on the Fish Market's cargo manifest.

from its inventory, equipped with a Cloud Cable Reefer Controller Interface, a Power-Managed Diesel Powered Generator with a Cloud Cable Genset Controller interface and Fuel Level and Fuel Cap Open Sensors, in "Ready" Status (Clean and Passed Pre-Trip Inspection) and with a "Very Good" rated maintenance record and history adequate for the "long-haul" Fish Market assignment and compatible with cargo monitoring requirements specified on the Fish Market's cargo manifest.

The Logistics Company's S2CT Asset Management System issues a request to its terminal's operations to pull and assemble the cab, chassis, and Reefer into a Reefer Transport Unit and top-off the Reefer generator's fuel level.  The Reefer Transport Unit's assigned driver, logs into the Logistics Company's S2CT Asset Management System through a Wi-Fi equipped Smartphone and executes a final communications test across the assembled Cab, Chassis, and Reefer (Smartphone Wi-Fi to chassis Wi-Fi enabled Cloud Cable to chassis Sub GHz sensors and Reefer Sub GHz Cloud Cable interfaces and sensors). Upon successful completion of the final communications test, and no anomalies detected, the Reefer Transport Unit departs through the Terminal's Gate for the Fish Market. Its departure time is communicated to the Logistics Company's S2CT Asset Management System and the system's ETA Analytics for potential update. The Reefer Transport Unit loses its Terminal provided Wi-Fi access to the Internet after its departure. The Reefer Transport Unit driver's smartphone, through its Wi-Fi mobile hotspot, can maintain a connection with the Reefer Transport Unit's assembly and communicate with the Logistics Company's S2CT Asset Management System as required.

The Reefer Transport Unit's assigned driver, logs into the Logistics Company's S2CT Asset Management System through a Wi-Fi equipped Smartphone and executes a final communications test across the assembled Cab, Chassis, and Reefer (Smartphone Wi-Fi to chassis Wi-Fi enabled Cloud Cable to chassis Sub GHz sensors and Reefer Sub GHz Cloud Cable interfaces and sensors). Upon successful completion of the final communications test, and no anomalies detected, the Reefer Transport Unit departs through the Terminal's Gate for the Fish Market. Its departure time is communicated to the Logistics Company's S2CT Asset Management System and the system's ETA Analytics for potential update. The Reefer Transport Unit loses its Terminal provided Wi-Fi access to the Internet after its departure. The Reefer Transport Unit driver's smartphone, through its Wi-Fi mobile hotspot, can maintain a connection with the Reefer Transport Unit's assembly and communicate with the Logistics Company's S2CT Asset Management System as required.

② Norwegian Fish Market

In preparation for the Logistics Company's Reefer Transport Unit's arrival, personnel at the Fish Market pack their chilled caviar cartons into Insulated Tubs that they lease from the Logistics Company. The Insulated Tub's barcode is scanned into the Fish Market's Order Entry Database along with the barcode on each of the caviar cartons creating a record of the caviar cargo in each tub. Finally, the Fish Market's packer scans the barcode on a

In preparation for the Logistics Company's Reefer Transport Unit's arrival, personnel at the Fish Market pack their chilled caviar cartons into Insulated Tubs that they lease from the Logistics Company. The Insulated Tub's barcode is scanned into the Fish Market's Order Entry Database along with the barcode on each of the caviar cartons creating a record of the caviar cargo in each tub. Finally, the Fish Market's packer scans the barcode on a ![]() Temperature Cargo Monitor (unique ID), activates the monitor and places it into the insulated tub with the cargo. Cargo Monitors record their ambient temperature throughout their journeys. Their accumulated data records are available to the Fish Market's end-customers when they receive their shipment of caviar, read through an available Near Field Communications (NFC) reader in a smartphone or other device. Note that some Cargo Monitor versions can continually ping their unique IDs, after being activated, and therefore their presence in a given cargo area can be detected.

Temperature Cargo Monitor (unique ID), activates the monitor and places it into the insulated tub with the cargo. Cargo Monitors record their ambient temperature throughout their journeys. Their accumulated data records are available to the Fish Market's end-customers when they receive their shipment of caviar, read through an available Near Field Communications (NFC) reader in a smartphone or other device. Note that some Cargo Monitor versions can continually ping their unique IDs, after being activated, and therefore their presence in a given cargo area can be detected.

The Logistics Company's Reefer Transport Unit arrives at the Fish Market's loading dock.  The loading dock's S2CT Asset Management Communications Hub recognizes the Reefer Transport Unit and timestamps its arrival. The Cab, Chassis and Reefer's Cloud Cables connect to the loading dock's Asset Communications Hub and use its Wi-Fi connection to the Internet to send the data they accumulated along their journey from the terminal to the Logistics Company's S2CT Asset Management System. The Fish Market's S2CT Asset Management System organizes the Reefer Transport Unit's shipping manifest and monitors the cargo loading to ensure that each Insulated Tub listed on the manifest is loaded into the Reefer. Some of the tubs have S2CT's Cargo Monitors in them and some don't. Some of the Cargo Monitors are Sub GHz enabled and some are not. Note, the Reefer's S2CT Cloud Cable is able to detect Sub GHz enabled Cargo Monitor IDs inside the Reefer's cargo area and records their presence until they move outside the Cloud Cable's Sub GHz coverage.

The loading dock's S2CT Asset Management Communications Hub recognizes the Reefer Transport Unit and timestamps its arrival. The Cab, Chassis and Reefer's Cloud Cables connect to the loading dock's Asset Communications Hub and use its Wi-Fi connection to the Internet to send the data they accumulated along their journey from the terminal to the Logistics Company's S2CT Asset Management System. The Fish Market's S2CT Asset Management System organizes the Reefer Transport Unit's shipping manifest and monitors the cargo loading to ensure that each Insulated Tub listed on the manifest is loaded into the Reefer. Some of the tubs have S2CT's Cargo Monitors in them and some don't. Some of the Cargo Monitors are Sub GHz enabled and some are not. Note, the Reefer's S2CT Cloud Cable is able to detect Sub GHz enabled Cargo Monitor IDs inside the Reefer's cargo area and records their presence until they move outside the Cloud Cable's Sub GHz coverage.

As cargo loading begins, the Logistics Company's S2CT Asset Management System engages alerts its Certified Climate Control Services Provider. The Climate Control Services Provider connects directly to the Reefer's Control Unit, through the Fish Market's Wi-Fi network and the Reefer's S2CT Cloud Cable, starts the Reefer's Genset and executes its Reefer start-up diagnostics. Upon successful completion of start-up, the Climate Control Services Provider sets the Reefer's operating parameters (-2 °C to 1 °C) and alarms (3 °C Δ between Cold and Return Airflows) to achieve the temperature conditions specified on the shipping manifest. Note that the Climate Control Services Provider might also verify that the specified climate conditions are consistent with the cargo's description, in this case, Chilled Caviar being transported in Insulated Tubs. The Certified Climate Control Services Provider, on behalf of the Norwegian Logistics Company, continues to receive and monitor data from the Reefer as it makes its way through its journey, opportunistically connecting to the Internet each time it encounters a cooperating Wi-Fi Access Point or mobile hotspot provided by a smartphone or tablet. When connected the Certified Climate Control Services Provider can also remotely manage the Reefers operating parameters and settings.

Upon completion of loading the cargo into the Reefer and before the Reefer's doors are closed and sealed, both the Reefer Transport Unit's driver, using the smartphone, and the Fish Market shipping manager, using a connected tablet, request an Exchange Verification (EV) from their respective Asset Management Systems. Watson compares the cargo designated as "shipped" by the Fish Market to the cargo designated as "received" by the Logistics Company. Watson returns an EV to both systems on a match and creates a Blockchain entry reflecting the change-of-custody. An "EV-Error" message is returned if Watson's comparison discovers a cargo discrepancy and no change-of-custody Blockchain is created until the discrepancy is resolved.

Upon a successful EV from Watson, the Reefer Transport Unit driver closes the Reefer's doors and grabs two Logistics Company Loop-Lock Electronic Digital Seals from the Cab's inventory.  The driver "touches" the Electronic Seal to the Reefer's S2CT Cloud Cable until the seal's LED lights, indicating that it is now paired with the Cloud Cable and the Reefer it's installed on.

The driver "touches" the Electronic Seal to the Reefer's S2CT Cloud Cable until the seal's LED lights, indicating that it is now paired with the Cloud Cable and the Reefer it's installed on.  The driver next installs the Electronic Seal loop wire through one of the Reefer's door lock-loop sets and then through the seal's cap, activating its "closed" beacon. The Electronic Seal is now armed and cannot be removed without interrupting its "closed" beacon. Once the Electronic Seal's closed beacon is interrupted it cannot be resumed. The second Electronic Seal is installed on the Reefer Controller's door in the same manner. Immediately after activation, the Cloud Cable sends each Electronic Seal's "closed" status to the Logistics Company's Asset Management System. This begins the Reefer's Green Lane monitoring. From that point forward the Cloud Cable continuously records the seals "closed" beacon and sends those accumulated records to the Logistics Company's S2CT Asset Management System each time it makes a connection to the Internet through Wi-Fi Access Points encountered along its journey, including a timestamp for when the "closed" beacon ended should that occur.

The driver next installs the Electronic Seal loop wire through one of the Reefer's door lock-loop sets and then through the seal's cap, activating its "closed" beacon. The Electronic Seal is now armed and cannot be removed without interrupting its "closed" beacon. Once the Electronic Seal's closed beacon is interrupted it cannot be resumed. The second Electronic Seal is installed on the Reefer Controller's door in the same manner. Immediately after activation, the Cloud Cable sends each Electronic Seal's "closed" status to the Logistics Company's Asset Management System. This begins the Reefer's Green Lane monitoring. From that point forward the Cloud Cable continuously records the seals "closed" beacon and sends those accumulated records to the Logistics Company's S2CT Asset Management System each time it makes a connection to the Internet through Wi-Fi Access Points encountered along its journey, including a timestamp for when the "closed" beacon ended should that occur.

Upon receiving the first door "closed" data from the Reefer's Cloud Cable while still at the Fish Market, the Logistics Company's S2CT Asset Management System sends the Reefer's Waybill and Green Lane Stamped Manifest to the appropriate Border Crossings and Customs offices along its projected route. The Reefer Transport Unit's departure from the Fish Market is timestamped in the Fish Market's S2CT Asset Management System and shared with the Logistics Company. The Logistics Company's S2CT Asset Management System evaluates the departure time and updates the Reefer Transport Unit's Railway Terminal ETA and shares it with the Railway Terminal. Effected downstream ETAs are also re-evaluated and communicated to the impacted supply chain partners as appropriate. Watson's Analytics are powerful enough to predict whether downstream impacts are meaningful or not and avoid unnecessary churn in the end-to-end system. The Reefer Transport Unit loses its Wi-Fi access to the Internet through the Fish Market's Wi-Fi access. Again, the Reefer Transport Unit driver's smartphone provides its mobile hotspot Wi-Fi as desired.

③ Norwegian Western Railway Terminal

The Reefer Transport Unit arrives at the Norwegian Western Railway Terminal where it establishes an Internet connection, through the terminal's Wi-Fi network, with the Logistics Company's S2CT Asset Management System.  The Reefer Transport Unit communicates all of the data its devices accumulated while traveling from the Fish Market to the Railway Terminal, to the Logistics Company's S2CT Asset Management System. The Railway Terminal's S2CT Asset Management System timestamps the Reefer Transport Unit's arrival.

The Reefer Transport Unit communicates all of the data its devices accumulated while traveling from the Fish Market to the Railway Terminal, to the Logistics Company's S2CT Asset Management System. The Railway Terminal's S2CT Asset Management System timestamps the Reefer Transport Unit's arrival.

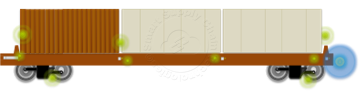

Railway Terminal personnel prepare to transfer the Reefer from the Reefer Transport Unit's chassis to a waiting railroad car equipped with its own Wi-Fi enabled S2CT Cloud Cable based asset monitoring local-area-network.  The railroad car's asset monitoring local-area-network is comprised of a single, railroad car-adapted, mechanically power-assisted battery-operated Wi-Fi enabled Hardened Rail Cloud Cable with multiple Sub GHz local-area-network antennas. The S2CT Cloud Cables Sub GHz antennas are strategically positioned around the railroad car to ensure reliable Sub GHz communications with Cloud Cables on containers it will carry. The Rail Cloud Cable will communicate data from itself and the assets it carries through Wi-Fi Access Points it encounters along its journey.

The railroad car's asset monitoring local-area-network is comprised of a single, railroad car-adapted, mechanically power-assisted battery-operated Wi-Fi enabled Hardened Rail Cloud Cable with multiple Sub GHz local-area-network antennas. The S2CT Cloud Cables Sub GHz antennas are strategically positioned around the railroad car to ensure reliable Sub GHz communications with Cloud Cables on containers it will carry. The Rail Cloud Cable will communicate data from itself and the assets it carries through Wi-Fi Access Points it encounters along its journey.

The Logistics Company's Reefer is loaded onto the railroad car, along with other containers, and its Cloud Cable communicates its presence to the railroad car's Cloud Cable.  The railroad car's Cloud Cable, connected to Rail Terminal's Wi-Fi network, communicates its railroad car-specific data to the Rail Carrier's S2CT Asset Management System, operational data and the IDs of the containers its carrying. The railroad car's Cloud Cable, using the same Wi-Fi connection to the Internet, sends data from each of the container's Cloud Cables to their respective Asset Management Systems. Blockchain-of-Custody entries are issued and recorded in the Logistics Company's and Rail Carrier's Blockchain ledgers.

The railroad car's Cloud Cable, connected to Rail Terminal's Wi-Fi network, communicates its railroad car-specific data to the Rail Carrier's S2CT Asset Management System, operational data and the IDs of the containers its carrying. The railroad car's Cloud Cable, using the same Wi-Fi connection to the Internet, sends data from each of the container's Cloud Cables to their respective Asset Management Systems. Blockchain-of-Custody entries are issued and recorded in the Logistics Company's and Rail Carrier's Blockchain ledgers.

At this point, the Rail Carrier knows that its railroad car is operationally ready for its journey, where precisely the railroad car is in the terminal, and that the Logistics Company's Reefer is loaded onto the correct railroad car.

The Logistics Company knows that its Reefer is loaded onto the railroad car, that the Electronic Seal installed in its door lock-loops has not been tampered with and remains closed, the Reefer's operational status and that its cab and chassis unit is now available for another container. The Fish Company gets an update from the Logistics Company.

The Climate Control Services Provider knows the Reefer's operational status and gets an opportunity to communicate directly with the Reefer's Controller to make changes or to communicate further operational actions.

Rail Terminal personnel continue to configure the train for its journey across Norway to Oslo. Communications between the various Cloud Cables and their owners continues using the terminal's Wi-Fi Internet connection until the train departs the terminal and moves beyond the terminal's Wi-Fi area of coverage. The departure timestamps for each railroad car and each of the containers they carry are recorded and communicated to the Rail Carrier's and Logistics Company's S2CT Asset Management Systems.

The S2CT Cloud Cables on each of the containers, and their respective sensors and interfaces devices, continue to collect data as the train makes its way across Norway to the Railway Terminal in Oslo. There are more than a dozen Rail Station Wi-Fi Access Points along this 8-hour journey. The Logistics Company's Reefer, carrying the Fish Company's chilled caviar and managed by the Certified Climate Control Services Provider,  has an opportunity to connect to the Internet at each of these Rail Stations through the railroad car's Wi-Fi enabled S2CT Cloud Cable. The railroad car's Cloud Cable can send data to and receive data from the Logistics Company and the Climate Control Services Provider. The Reefer can send traditional reefer data as well as "event" messages alerting the Logistics Company and Climate Control Services Provider of important changes in the reefer's operation, return airflow temperature is too high, the reefer's fuel level has changed more than expected, the Reefer's generator has malfunctioned, an Electronic Seal status has changed to "open", etc. The Reefer's Cloud Cable can also receive data from either the Logistics Company or Climate Control Services Provider, open a vent, set the temperature to a new level, retrieve reefer control "alarms", turn the Reefer's generator off or on immediately or after a period of time, etc.

has an opportunity to connect to the Internet at each of these Rail Stations through the railroad car's Wi-Fi enabled S2CT Cloud Cable. The railroad car's Cloud Cable can send data to and receive data from the Logistics Company and the Climate Control Services Provider. The Reefer can send traditional reefer data as well as "event" messages alerting the Logistics Company and Climate Control Services Provider of important changes in the reefer's operation, return airflow temperature is too high, the reefer's fuel level has changed more than expected, the Reefer's generator has malfunctioned, an Electronic Seal status has changed to "open", etc. The Reefer's Cloud Cable can also receive data from either the Logistics Company or Climate Control Services Provider, open a vent, set the temperature to a new level, retrieve reefer control "alarms", turn the Reefer's generator off or on immediately or after a period of time, etc.

Utilizing data from the railroad car carrying the Reefer, Watson continuously estimates its location, as it travels along, latitude 60.627° N and longitude 6.399° E, +/- 15 meters, with 97% probability. Accuracy along a "known" rail track will be high and will continuously improve over time with more and more historical data. Watson uses accumulated historical data from trains that traveled along the same route, current railway data, weather data, and the periodic updates from the railroad car passing a Wi-Fi APs to estimate its location. Watson re-evaluates and retro-updates previously saved estimated locations, already stored in Asset Management Systems database, as necessary. That process maximizes the eventual correlation between timestamped asset locations and events.

The Cloud Cable on the railroad car carrying the Logistics Company's Reefer relays its data to the Logistics Company's S2CT Asset Management System each time the railroad car's Cloud Cable makes a Wi-Fi Internet connection. Watson continuously evaluates the Reefer's projected ETAs and based on the Reefer's new estimated location, updates the remaining projected destination ETA's as appropriate. Logistics Company personnel, drivers, terminal workers and office administration staff are all able to securely view and monitor their private data and alarms as well as data shared with them by their supply chain partners, from anywhere, on any device capable of connecting to the Internet. Similarly, the Fish Market and Rail Carrier have access to their private data and shared data.

The Cloud Cable on the railroad car carrying the Logistics Company's Reefer relays its data to the Logistics Company's S2CT Asset Management System each time the railroad car's Cloud Cable makes a Wi-Fi Internet connection. Watson continuously evaluates the Reefer's projected ETAs and based on the Reefer's new estimated location, updates the remaining projected destination ETA's as appropriate. Logistics Company personnel, drivers, terminal workers and office administration staff are all able to securely view and monitor their private data and alarms as well as data shared with them by their supply chain partners, from anywhere, on any device capable of connecting to the Internet. Similarly, the Fish Market and Rail Carrier have access to their private data and shared data.

③b Norwegian Oslo Railway Terminal

The train arrives at the Oslo Railway Terminal where the Logistics Company's Reefer  will be loaded with additional authorized Green Lane Compliant cargo and be transferred onto another railroad car on a train traveling to the Shipping Terminal in Sodertalje, Sweden.

will be loaded with additional authorized Green Lane Compliant cargo and be transferred onto another railroad car on a train traveling to the Shipping Terminal in Sodertalje, Sweden.

Once in the Railway Terminal, the Logistics Company's Reefer's S2CT Cloud Cable is continuously connected to the Internet through the terminals Wi-Fi network, sending data to the Logistics Company's, Rail Carrier's and Certified Climate Control Services Provider's S2CT Asset Management Systems.

The Reefer is removed from the arriving railroad car and moved to the terminal's loading area. A Blockchain-of-Custody is created in the Oslo Rail Terminals Asset Management System's Ledger.

The Logistics Company monitors its Reefer's electronic door seal being broken, to open the reefer's door, "as planned" at the Oslo Railway Terminal by authorized personnel. A manifest for additional cargo, insulated tubs loaded with chilled salmon with climate specifications, was shared with and authorized by the Climate Control Services Provider prior to making the decision to consolidate it in the Reefer already carrying chilled caviar. The Climate Control Services Provider downloaded temporary climate parameters to the Reefer's Controller and Genset, specifically designed to manage the Reefer's climate during this mid-journey door-open period.

The additional cargo is scanned and loaded into the Reefer by authorized terminal personnel. The terminal personnel execute an EV to ensure that all of new cargo and nothing else was loaded into the Reefer. Upon the successful EV, the doors are reclosed, and another S2CT Electronic Seal is "associated" with the Reefer and installed in its door loop-locks. All of this is monitored by the Logistics Company's S2CT Asset Management System, noting in particular, that the original Electronic Seal door seal was removed, exposing the Reefer's Green Lane Status. The Logistics Company, using the data in its Asset Management System collected during this interruption, determines that the interruption occurred as planned, the new cargo was compliant with the Reefer's original Green Lane Designation, and was loaded by authorized personnel at the prescribed location. The Logistics Company forwards a new, updated, Green Lane Stamped Manifest to the appropriate Border Crossings and Customs offices along the rest of the Reefer's projected route.

The Climate Control Services Provider is also monitoring this process and upon its completion, on door-closed, resets the Reefer's operating parameters for the remaining journey.

The Reefer is loaded onto the designated railroad car with other containers and moved into the train.  The Reefer's S2CT Cloud Cable communicates its presence to the railroad car's Cloud Cable which already has an established connection to the Internet through the Rail Terminal's Wi-Fi Network. A Blockchain-of-Custody is created in the Rail Carrier's Asset Management System's Ledger. The Rail Terminal is tracking the Reefer and railroad car through this process to ensure that it's executed correctly and as planned by its S2CT Asset Management System and Watson. The Rail Terminal's S2CT Asset Management System and Watson raise and communicate alerts and alarms to appropriate personnel and stakeholders when things are not going as planned, including alerts relayed from the Climate Control Services Provider. Everyone is on the same page and Watson is helping them all monitor "execution".

The Reefer's S2CT Cloud Cable communicates its presence to the railroad car's Cloud Cable which already has an established connection to the Internet through the Rail Terminal's Wi-Fi Network. A Blockchain-of-Custody is created in the Rail Carrier's Asset Management System's Ledger. The Rail Terminal is tracking the Reefer and railroad car through this process to ensure that it's executed correctly and as planned by its S2CT Asset Management System and Watson. The Rail Terminal's S2CT Asset Management System and Watson raise and communicate alerts and alarms to appropriate personnel and stakeholders when things are not going as planned, including alerts relayed from the Climate Control Services Provider. Everyone is on the same page and Watson is helping them all monitor "execution".

The Reefer's Oslo Rail Terminal departure is timestamped in the Rail Terminal's, Rail Carrier's and Logistics Company's S2CT Asset Management Systems. ETAs are re-evaluated and changes communicated across the supply chain as appropriate.

The Logistics Company knows that its Reefer has had additional Green Lane cargo loaded into it without violating its Green Lane process, the Reefer's doors were resealed, the Reefer's Controller door remains "closed", that its Reefer's climate has been maintained within the specifications of both of its cargoes as per their respective manifests, that the Reefer is now being carried by a different railroad car in a different train heading for the Shipping Terminal in Sodertalje, Sweden, and that the Reefer has departed the Oslo Rail Terminal.

④ Shipping / Rail Terminal in Sodertalje Sweden

There are more than a dozen railway stations, with Wi-Fi coverage, along the six or so hour rail journey from Oslo and Sodertalje. The Logistics Company's Reefer communicates with the Logistics Company's S2CT Asset Management System at each Wi-Fi connection. Again, Watson is continually estimating the Reefer's location as it travels, making adjustments as necessary at each Wi-Fi connection.

The Logistics Company's Reefer communicates with the Logistics Company's S2CT Asset Management System at each Wi-Fi connection. Again, Watson is continually estimating the Reefer's location as it travels, making adjustments as necessary at each Wi-Fi connection.

The train and Reefer arrive at the Shipping Terminal in Sodertalje. The Logistics Company, Rail Carrier, and Shipping Terminal are apprised of the Reefer's arrival upon its connecting to the terminal's Wi-Fi network.

Shipping Terminal personnel prepare to transfer the Reefer from the train's railroad car onto a waiting vessel. The Reefer is moved from the railroad car to the terminal's staging area along with other containers that will be loaded on the same vessel. The Reefer's generator is turned off for voyage. Watson, considering that the generator will not be running when the Reefer is being transported by vessel, projects, for the Logistics Company's S2CT Asset Management System, that the reefer's generator will need to be topped-off in Gdansk and then again at the border of Kazakhstan and China.

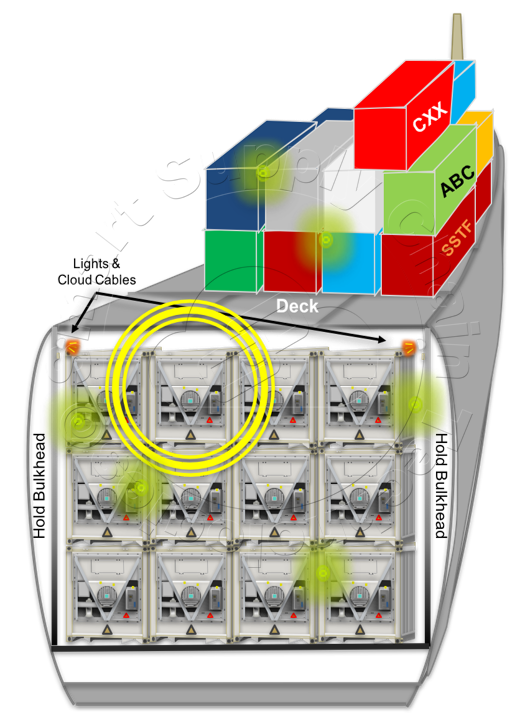

An EV and Blockchain-of-Custody is created and shared with the Logistic Company, the Rail Carrier, and the Shipping Terminal. The Reefer's position on the vessel has been selected on the vessel's load map by the Logistics Company and the Vessel Operator. The vessel load map has been communicated to the shipping terminal. The Reefer is moved into position in the loading area of the designated vessel, verified by the Terminal Operation's S2CT Asset Management System and Watson using terminal data and Wi-Fi triangulation to track the Reefer's movements and the position of the designated vessel. The Climate Control Services Provider communicates an operational profile to the Reefer's Controller for use while in the vessel's cargo-hold where the ambient environment can be extreme. The Reefer is moved into the vessel's below-deck cold-chain cargo-hold at the top of the second port side reefer stack by the terminal's crane, again using Watson Wi-Fi triangulation to monitor and assist this precision operation. The Reefer's 3-axes geospatial position can be determined by Watson with centimeter accuracy. Once loaded into the vessel's cargo-hold, the Reefer's S2CT Cloud Cable establishes a Sub GHz connection with cargo-hold Cloud Cables that connect to the vessel's bridge through power-line modems. Wireless communications from within the metal enclosed cargo-hold is difficult and expensive.  When the below-deck cold-chain cargo-hold is fully loaded and before the cargo-hold's hatch cover is closed, vessel crew ensure that the Reefer's integrated power generator is off and connects the Reefer to vessel-power for the twenty-hour or so voyage to Poland. The Logistics Company takes advantage of this period to have a number of its empty reefers loaded onto the vessel and connect to power for Reefer Pre-Trip-Inspections (PTI) scheduled to run during the voyage. The empty reefers, assuming they exit PTI successfully, will be loaded with cargo and deployed from the terminal in Poland. All of this is closely monitored by Shipping Terminal Operations and the vessel's Chief Officer or Cargo Engineer. Any anomalies that occur during the transfer process are immediately communicated to both Shipping Terminal Operation and the vessel's Chief Officer for remedy before the vessel departs. The Reefer's operation is monitored closely by the Climate Control Services Provider during this transfer onto the vessel to ensure the Reefer's seamless operation. The below-deck cold-chain cargo-hold hatch is closed and loading continues on the deck above until the vessel completes loading and departs for Gdansk, Poland.

When the below-deck cold-chain cargo-hold is fully loaded and before the cargo-hold's hatch cover is closed, vessel crew ensure that the Reefer's integrated power generator is off and connects the Reefer to vessel-power for the twenty-hour or so voyage to Poland. The Logistics Company takes advantage of this period to have a number of its empty reefers loaded onto the vessel and connect to power for Reefer Pre-Trip-Inspections (PTI) scheduled to run during the voyage. The empty reefers, assuming they exit PTI successfully, will be loaded with cargo and deployed from the terminal in Poland. All of this is closely monitored by Shipping Terminal Operations and the vessel's Chief Officer or Cargo Engineer. Any anomalies that occur during the transfer process are immediately communicated to both Shipping Terminal Operation and the vessel's Chief Officer for remedy before the vessel departs. The Reefer's operation is monitored closely by the Climate Control Services Provider during this transfer onto the vessel to ensure the Reefer's seamless operation. The below-deck cold-chain cargo-hold hatch is closed and loading continues on the deck above until the vessel completes loading and departs for Gdansk, Poland.

Vessel

The vessel looks much like a terminal with S2CT Sub GHz Cloud Cables installed in each of its below deck cold-chain cargo-holds and across its open deck to connect Cloud Cables on assets with the vessel's bridge and communications systems. Below-deck Reefer power can be continuously monitored by the vessel's crew from the safety of the bridge during the voyage. The vessel's ship-to-shore communications system can be used to communicate data and alerts to the Logistics Company and Climate Control Services Provider when necessary. The vessel can relay commands, from the Climate Control Services Provider, to any Cloud Cable equipped Reefer below its deck, again from the relative safety of the ship's bridge.

The vessel looks much like a terminal with S2CT Sub GHz Cloud Cables installed in each of its below deck cold-chain cargo-holds and across its open deck to connect Cloud Cables on assets with the vessel's bridge and communications systems. Below-deck Reefer power can be continuously monitored by the vessel's crew from the safety of the bridge during the voyage. The vessel's ship-to-shore communications system can be used to communicate data and alerts to the Logistics Company and Climate Control Services Provider when necessary. The vessel can relay commands, from the Climate Control Services Provider, to any Cloud Cable equipped Reefer below its deck, again from the relative safety of the ship's bridge.

Watson continuously re-evaluates the vessel's projected ETA based on historical data, the vessel's load profile, weather data across the vessel's projected route and vessel specific GPS data from a variety of shipping industry sources, VesselFinder for example. Watson can inform the vessel of vessel traffic at the destination terminal and recommend changes in speed and route to optimize its arrival time and unloading. Some industry experts estimate average worldwide vessel fuel savings could be as high as 20% by timing a vessel's arrival with its scheduled cargo unloading, coordinated with the cargo's movement through and out of the terminals. On the West Coast of the U.S., at the Port of Long Beach in California for example, this savings can be as high as 35% with vessel wait times typically between 4 and 5 days but often longer, incredibly, a 10,000-teu CSCL vessel had to wait 32 days for its cargo to be unloaded in late 2014. Once in port, unloading typically takes a single day.

During the vessel's journey, the Reefer issues a temperature alert for the Climate Control Services Provider, the difference between the Reefer's in flowing cold-air temperature and the return-air temperature exceeds the setting communicated to the Reefer before the vessel departed Sweden. The alert message, with related data, is communicated to the vessel's bridge and is then relayed to the Climate Control Services Provider. The Climate Control Services Provider sends instructions to the Reefer to close its vents and reduce its temperature setting by 1 °C. The instruction is relayed through the vessel's communications systems to the vessel's Cloud Cable in the cargo-hold, to the Reefer's Cloud Cable, and finally to the Reefer's Controller for execution.

This reefer temperature alert, and its associated data, is also sent to the Logistics Company's Maintenance Database where Watson evaluates it along its and other reefer's historical data. If Watson's evaluation suggests that the Reefer is failing or might fail in the near future, the Logistics Company forwards the data to its Global Maintenance Service Provider. The Maintenance Service Provider further evaluates the data for the possible scheduling of a physical inspection or repair, at an Affiliate Service Center along the Reefer's planned travel route. The Global Maintenance Service Provider acts as a broker for "certified" Container Service Centers around the world that can be called upon to service containers traveling anywhere in the global supply chain. In this case, the Global Maintenance Service Provider, using the data shared by the Logistics Company, schedules an inspection at the Druzhba Rail Terminal, in Kazakhstan, where the railroad car carrying the Reefer is scheduled to stop to have its bogie wheels adjusted for the rail gauge ahead, in China, and to get its power-generator refueled.

⑤ ⑥ Shipping / Rail Terminal in Gdansk Poland

The vessel arrives dockside at the Gdansk Shipping Terminal and begins unloading its containers immediately, following the vessel's cargo unloading-plan. The deck-level containers on the hatch-cover of the cargo-hold where the Logistics Company's Reefer is, are offloaded and the hatch-cover is opened. Once the hatch-cover is opened, the vessel's crew disconnects vessel-power from the reefers in the cargo-hold. The reefer Cloud Cables begin to connect to the Internet through the Shipping Terminal's Wi-Fi network.

The Logistics Company's Reefer communicates the data it accumulated during its voyage, through its Cloud Cable's linked connection to the terminals Wi-Fi network, to the Logistics Company's S2CT Asset Management System. Data like its timestamped arrival, reefer controller trip data, reefer generator fuel level, and Electronic Seal status. Based on the Reefer's door's Electronic Seal status data, "closed", the Logistics Company leaves the Reefer's Green Lane designation in place. Had the status of that Electronic Seal on the Reefer's doors changed to "open", it would be up to the Logistics Company to gauge the risk that the container's cargo could have been tampered with and to take an appropriate action to protect its Green Lane privileges, remove the container's Green Lane designation.

The Logistics Company's Reefer also communicates its arrival at the shipping terminal, its power status, its generator fuel level and top level reefer data to the Climate Control Services Provider. The Logistics Company issues a Work Order to the shipping terminal requesting that the Reefer's generator fuel be "topped-off" before the Reefer departs the terminal. The Climate Control Services Provider might request additional data from the Reefer's Controller because of the temperature alert issued during the voyage, for further analysis. The Climate Control Services Provider communicates a new reefer operational profile to the Reefer's Controller, for the remainder of the reefer's journey.

The Reefer is removed from the vessel's cargo-hold by the terminal's crane and placed on a yard-truck for transport to a designated rail-staging area. The Logistics Company's Reefer is still subject to random inspection by Polish Customs but as a Green Lane designated shipment it moves to the designated rail staging area without delay.

Typically, vessels are loaded precisely in accordance with a vessel cargo load planning to ensure proper load distribution with only some thought regarding the cargo's unloading. Unloading is typically at the terminal's crane operator's discretion, opportunistically unloading assessable containers. Watson can change this by optimizing the load plan, the unload plan and the accessibility of container groups at each port of call. Using this power, coupled with vessel traffic control, Green Lane and workflow optimization, all of the containers on the vessel that will travel together on the train leaving the shipping terminal will be unloaded and moved to the appropriate rail staging and loading areas at nearly the same time. This ensures that the train will not be delayed waiting for a buried container and will depart as close to its planned departure time as possible.

Once in the rail-staging area, the Reefer generator's diesel fuel tank is topped-off in accordance with Logistics Company work order. The Logistics Company, through the Reefer's Cloud Cable connection to the Internet, monitors the generators fuel cap being "open" and the tank's fuel level returning to "full" after the cap is "closed" again.

Once in the rail-staging area, the Reefer generator's diesel fuel tank is topped-off in accordance with Logistics Company work order. The Logistics Company, through the Reefer's Cloud Cable connection to the Internet, monitors the generators fuel cap being "open" and the tank's fuel level returning to "full" after the cap is "closed" again.  The Reefer is restarted and moved again to the shipping terminal's international-rail loading area where it will be loaded onto a designated railroad car with other containers that will depart the terminal on the same train. The designated railroad car is one that is assigned to travel from Gdansk, Poland, to Xinyu, China, and is equipped with an adjustable bogie to accommodate the track gauge changes along the planned route, and a Wi-Fi enabled S2CT Rail Cloud Cable asset monitoring local-area-network. The railroad car is incorporated into the train and prepares to depart the Gdansk Shipping Terminal. This process is tracked and monitored by Asset Management Systems at the shipping terminal, the rail carrier, and the Logistics Company, each sharing critical data with the other, to ensure that the Reefer is loaded onto the correct railroad car and incorporated into the correct train. The Shipping Terminal's S2CT Asset Management System, ultimately responsible for managing this process, uses Watson to raise and communicate alerts and alarms to appropriate terminal personnel when things are not going as planned. The Climate Control Services Provider and Maintenance Service Provider independently continue to monitor the Reefer's operation.

The Reefer is restarted and moved again to the shipping terminal's international-rail loading area where it will be loaded onto a designated railroad car with other containers that will depart the terminal on the same train. The designated railroad car is one that is assigned to travel from Gdansk, Poland, to Xinyu, China, and is equipped with an adjustable bogie to accommodate the track gauge changes along the planned route, and a Wi-Fi enabled S2CT Rail Cloud Cable asset monitoring local-area-network. The railroad car is incorporated into the train and prepares to depart the Gdansk Shipping Terminal. This process is tracked and monitored by Asset Management Systems at the shipping terminal, the rail carrier, and the Logistics Company, each sharing critical data with the other, to ensure that the Reefer is loaded onto the correct railroad car and incorporated into the correct train. The Shipping Terminal's S2CT Asset Management System, ultimately responsible for managing this process, uses Watson to raise and communicate alerts and alarms to appropriate terminal personnel when things are not going as planned. The Climate Control Services Provider and Maintenance Service Provider independently continue to monitor the Reefer's operation.

As the train departs the Gdansk Shipping Terminal International Rail Facility and passes through its exit gate, each Cloud Cable, on railroad cars and container assets, acknowledges and timestamps its depart and communicates it to the appropriate Asset Management System.

Blockchain-of-Custody entries were created when the shipping terminal's crane engaged the Reefer and moved it into the terminal and again when the Reefer was transferred onto the Rail Carrier's railroad car.

The Logistics Company's Reefer is on its way to Xinyu China with an expected refueling and maintenance inspection at the Druzhba Rail Terminal, in Kazakhstan. The Reefer will communicate reefer data, through the railroad car's Wi-Fi enabled S2CT Cloud Cable,  to the Logistics Company's and Climate Control Services Provider's Asset Management Systems as it makes its way and encounters Wi-Fi access points. The railroad car's Wi-Fi enabled Cloud Cable will also communicate railroad car data to the rail carrier's Asset Management System. All three will share data among themselves and the Logistics Company will also share data with the Maintenance Service Provider, the Fish Company and other stakeholders as appropriate. The Logistics Company's S2CT Asset Management System, using Watson, will use historical data and data received from the Reefer as it passes Wi-Fi access points along its journey to track the Reefer's progress and continuously reevaluate the progress and projected ETA's.

to the Logistics Company's and Climate Control Services Provider's Asset Management Systems as it makes its way and encounters Wi-Fi access points. The railroad car's Wi-Fi enabled Cloud Cable will also communicate railroad car data to the rail carrier's Asset Management System. All three will share data among themselves and the Logistics Company will also share data with the Maintenance Service Provider, the Fish Company and other stakeholders as appropriate. The Logistics Company's S2CT Asset Management System, using Watson, will use historical data and data received from the Reefer as it passes Wi-Fi access points along its journey to track the Reefer's progress and continuously reevaluate the progress and projected ETA's.

Druzhba Rail Terminal

The train arrives at the Druzhba Rail Terminal where the bogies on the train's railroad cars will be adjusted for the track gauge ahead in China. The Logistics Company's Reefer will be inspected by the Certified Service Center personnel, arranged by the Global Maintenance Service Provider, and have its diesel fuel topped-off for the remainder of the journey.

Once in the Rail Terminal, the Logistics Company's Reefer's Cloud Cable is continuously connected to the Internet through the terminal's Wi-Fi network and the railroad car's Cloud Cable. The Reefer sends its data to the Logistics Company's and Climate Control Services Provider's Asset Management Systems. The railroad car sends it data to the Rail Carrier's Asset Management System. The Logistics Company shares data with its Global Maintenance Service Provider. The Global Maintenance Service Provider and their affiliated Certified Service Center communicate directly with each other and share data with the Logistics Company.

The railroad car's bogie is adjusted, the Reefer generator's fuel is topped-off, and the Reefer inspection results are recorded and addressed as required before the Reefer departs the Rail Terminal.

The Reefer's Cloud Cable is programmed to timestamp and issue an immediate Electronic Seal Status Change Alert should the status of any of the Electronic Seals change from "closed" to "open". The Status Alert is communicated immediately to the Logistics Company's Asset Management System when the Reefer's Cloud Cable has a connection to the Internet. With no immediate connection to the Internet, the Cloud Cable would store the Status Alert until it next connects.

A Status Change Alert from an Electronic Seal on the container's doors is particularly important to the Logistics Company as it is the Logistics Company's responsibility to designate and then ensure a container remains Green Lane compliant throughout its supply chain journey. An Electronic Seal is simply a tool to assist companies to monitor their container shipments. Should the Reefer's Electronic Seal on its doors be opened, unexpectedly, by presumably unauthorized persons, the Reefer's cargo would be at risk of being tampered with, cargo removed, added or changed in some unexpected way. In such a case, the Logistics Company is likely to remove the Reefer's Green Lane designation and alert Border Protection and Customs along the Reefer's remaining route of the change. Should the Logistics Company not change the Reefer's Green Lane designation and the Reefer be "randomly" inspected by Customs and or Border Protection and be discovered to be non-compliant with Green Lane, the Logistics Company risk losing its "fast-track" Green Lane privileges and their competitive advantages.

The train and Reefer departure from the Druzhba Rail Terminal is timestamped in the Logistics Company's and Rail Carrier's Asset Management Systems. The Logistics Company's Asset Management System, using Watson, will again use historical data and data received from the Reefer as it departs the Rail Terminal to reevaluate the Reefer's projected ETA's. The Logistics Company's S2CT Asset Management System will notify any downstream stakeholders of any changes that affect them.

⑦ Xinyu Rail Terminal

The train and Logistics Company's Reefer finally reach the Xinyu Rail Terminal, after a 15-day journey, where the Reefer and its cargo will clear Chinese Customs, be loaded onto a Reefer Transport Unit and be delivered to a nearby Seafood Distributor Center in Ji'an.

Once in the Xinyu Railway Terminal, the Logistics Company's Reefer's Cloud Cable is continuously connected to the Internet through the terminal's Wi-Fi network and communicates with the Logistics Company's and Climate Control Services Provider's S2CT Asset Management Systems. The railroad car's Cloud Cable sends its railroad car operational data to the Rail Carrier's Asset Management Systems and its Wi-Fi connection data the Rail Terminal.

The Logistics Company's Reefer is unloaded from the railroad car and moved to a "Local-Transfer" staging area in the terminal to await Customs clearance and loading onto a Reefer Transport Unit arriving at the Rail Terminal just as the Reefer is reaching the staging area. A Blockchain-of-Custody is recorded in the Xinyu Rail Terminal's Asset Management System and noted in the Norwegian Logistic Company's Asset Management System. Watson's ETA monitoring has done its job well. The Reefer clears Customs seamlessly as a Green Lane shipment and is ready to continue on its journey to its next destination, the China Seafood Distribution Center in Xinyu.

The Norwegian Logistics Company has arranged for a local Chinese Logistics Company to transport the Reefer to the Seafood Distribution Center. The Norwegian Logistics Company requested a "connected" Reefer Transport Unit to provide communications between its Reefer and its Asset Management System during its journey.  Their Reefer Transport Unit is comprised of a connected chassis with a Wi-Fi enabled Cloud Cable and a network of Sub GHz sensors monitoring the chassis: tire pressures, lights, and axle, and a truck cab.

Their Reefer Transport Unit is comprised of a connected chassis with a Wi-Fi enabled Cloud Cable and a network of Sub GHz sensors monitoring the chassis: tire pressures, lights, and axle, and a truck cab.  The connected Transport Unit's truck cab is equipped with a Standard Cloud Cable and its local-area-network of sensors: fuel level, lights, tire pressures, and axle. The Reefer Transport Unit's driver will have a Wi-Fi enabled Smartphone connected to the Internet through a local telecommunications service provider.

The connected Transport Unit's truck cab is equipped with a Standard Cloud Cable and its local-area-network of sensors: fuel level, lights, tire pressures, and axle. The Reefer Transport Unit's driver will have a Wi-Fi enabled Smartphone connected to the Internet through a local telecommunications service provider.

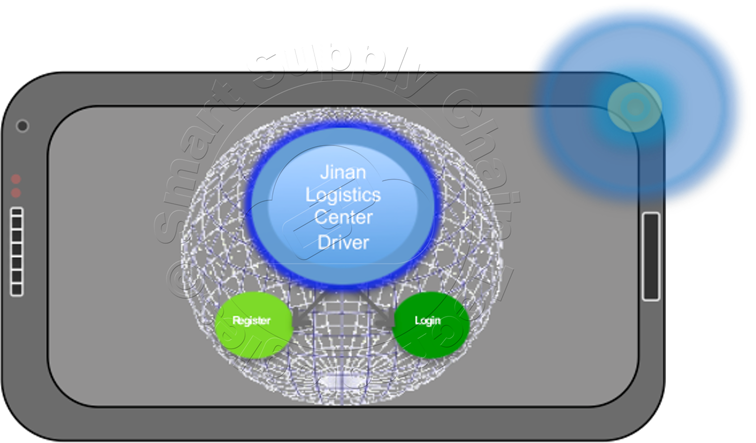

The Reefer is loaded onto the Transport Unit's chassis. A Blockchain-of-Custody is recorded in the Chinese Logistics Company's Asset Management System and noted in the Norwegian Logistic Company's Asset Management.  The Reefer Transport Unit's driver logs into the Chinese Logistics Company's Asset Management System through the Smartphone's connection to the Internet. The driver executes a communications test across the assembled Cab, Chassis and Reefer.

The Reefer Transport Unit's driver logs into the Chinese Logistics Company's Asset Management System through the Smartphone's connection to the Internet. The driver executes a communications test across the assembled Cab, Chassis and Reefer.  Upon successful completion of the communications test, the Reefer Transport Unit departs through the Rail Terminal's Gate for the Seafood Distribution Center. Its departure time is communicated to both the Chinese and Norwegian Logistics Company's Asset Management Systems and the system's ETA Analytics. The Reefer's departure and projected ETA is shared with the Seafood Distribution Center. The Chinese Logistics Company and Seafood Distribution Center S2CT Asset Management System monitors the Reefer Transport Unit's progress through the driver's smartphone. The Reefer Transport Unit driver's smartphone, through its Wi-Fi mobile hotspot, can maintain a connection with the Reefer Transport Unit's assembly and communicate with the Chinese Logistics Company's S2CT Asset Management System as required along its journey to the Seafood Distribution Center, a little more than a one hour trip.

Upon successful completion of the communications test, the Reefer Transport Unit departs through the Rail Terminal's Gate for the Seafood Distribution Center. Its departure time is communicated to both the Chinese and Norwegian Logistics Company's Asset Management Systems and the system's ETA Analytics. The Reefer's departure and projected ETA is shared with the Seafood Distribution Center. The Chinese Logistics Company and Seafood Distribution Center S2CT Asset Management System monitors the Reefer Transport Unit's progress through the driver's smartphone. The Reefer Transport Unit driver's smartphone, through its Wi-Fi mobile hotspot, can maintain a connection with the Reefer Transport Unit's assembly and communicate with the Chinese Logistics Company's S2CT Asset Management System as required along its journey to the Seafood Distribution Center, a little more than a one hour trip.

⑧ Ji'an Seafood Distribution Center

The Logistics Company's Reefer arrives at the Ji'an Seafood Distribution. The Seafood Distribution Center's Wi-Fi network connects with the Cloud Cable on the Transport Unit's chassis.  The Transport Unit's arrival is timestamped by the Norwegian Logistics Company, the Chinese Logistics Company, and the Seafood Distribution Center. A Blockchain-of-Custody is recorded in the Seafood Distribution Center's Asset Management System and noted in the Norwegian Logistic Company's Asset Management System. The Reefer's, and its cargo's, arrival at the Seafood Distribution is shared by both the Norwegian Logistics Company and Norwegian Fish Market.

The Transport Unit's arrival is timestamped by the Norwegian Logistics Company, the Chinese Logistics Company, and the Seafood Distribution Center. A Blockchain-of-Custody is recorded in the Seafood Distribution Center's Asset Management System and noted in the Norwegian Logistic Company's Asset Management System. The Reefer's, and its cargo's, arrival at the Seafood Distribution is shared by both the Norwegian Logistics Company and Norwegian Fish Market.

The Norwegian Logistics Company downloads the entire Reefer's Data Logger 15-day Trip Data Record to its Archives. The Reefer's generator is remotely powered off by the Climate Control Services Provider.  The Reefer's Electronic Seal on its doors is broken and the Reefer's doors are opened by the Chinese Logistics Company's Reefer Transport Unit driver. The Reefer's Electronic Seal Status Change Alert is recorded in the Norwegian Logistics Company's and Seafood Distribution Center's Asset Management Systems.

The Reefer's Electronic Seal on its doors is broken and the Reefer's doors are opened by the Chinese Logistics Company's Reefer Transport Unit driver. The Reefer's Electronic Seal Status Change Alert is recorded in the Norwegian Logistics Company's and Seafood Distribution Center's Asset Management Systems.  The Insulated Tubs are unloaded from the Reefer's cargo area and scanned into the Seafood Distribution Center's Receiving Database. A detailed Exchange Verification, EV, is executed by the Seafood Distribution Center's Asset Management System. Upon verification that everything shipped by the Norwegian Fish Market was received by the Ji'an Seafood Distribution Center an EV is recorded in the Norwegian Fish Market's, Norwegian Logistics Company's, Chinese Logistics Company's and Ji'an Seafood Distribution Center's Asset Management Systems. The Reefer Transport Unit departs the Seafood Distribution Company's property.

The Insulated Tubs are unloaded from the Reefer's cargo area and scanned into the Seafood Distribution Center's Receiving Database. A detailed Exchange Verification, EV, is executed by the Seafood Distribution Center's Asset Management System. Upon verification that everything shipped by the Norwegian Fish Market was received by the Ji'an Seafood Distribution Center an EV is recorded in the Norwegian Fish Market's, Norwegian Logistics Company's, Chinese Logistics Company's and Ji'an Seafood Distribution Center's Asset Management Systems. The Reefer Transport Unit departs the Seafood Distribution Company's property.

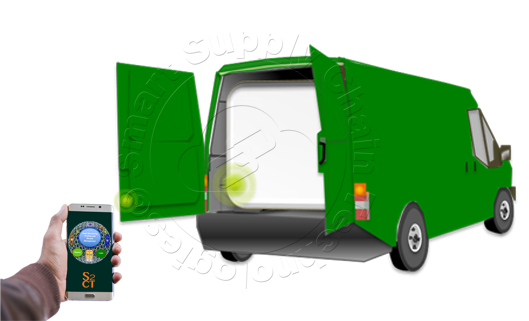

A "Cold-Box" delivery van, from a local Ji'an Logistics Company hired by the Ji'an Seafood Distribution Company, arrives shortly after the Reefer Transport Unit departs.  A "Cold-Box" is a small, precision, 12 VDC refrigeration unit that is designed to fit in or on a small delivery truck and temporarily convert it into a cold-chain transport vehicle.

A "Cold-Box" is a small, precision, 12 VDC refrigeration unit that is designed to fit in or on a small delivery truck and temporarily convert it into a cold-chain transport vehicle.  The Cold-Box is equipped with a Wi-Fi enabled Cloud Cable Interface capable of connecting the Cold-Box's controller to the Internet through a driver's Smartphone. The Ji'an Logistics Company remotely sets the Cold-Box's operational settings for the chilled caviar cargo. Cartons of chilled caviar are removed from two of the Insulated Tubs along with their Cargo Monitors, are scanned into the Seafood Distribution Center's Shipping Database, and loaded into the van's Cold-Box. The Insulated Tubs are keep by the Ji'an Seafood Distribution Company for its future "leased" use or future use by the Norwegian Logistics Company. The disposition of the empty Insulated Tubs is managed by Norwegian Logistics Company's Asset Management System in cooperation with the Ji'an Seafood Distribution Center. Managing this roaming inventory of Insulated Tubs is another challenge that the Norwegian Logistics Company looks to its S2CT Asset Management System and Watson to keep track of. The Ji'an Seafood Distribution Center executes a Blockchain-of-Custody entry and the Ji'an Logistics Company's driver executes an EV before departing.

The Cold-Box is equipped with a Wi-Fi enabled Cloud Cable Interface capable of connecting the Cold-Box's controller to the Internet through a driver's Smartphone. The Ji'an Logistics Company remotely sets the Cold-Box's operational settings for the chilled caviar cargo. Cartons of chilled caviar are removed from two of the Insulated Tubs along with their Cargo Monitors, are scanned into the Seafood Distribution Center's Shipping Database, and loaded into the van's Cold-Box. The Insulated Tubs are keep by the Ji'an Seafood Distribution Company for its future "leased" use or future use by the Norwegian Logistics Company. The disposition of the empty Insulated Tubs is managed by Norwegian Logistics Company's Asset Management System in cooperation with the Ji'an Seafood Distribution Center. Managing this roaming inventory of Insulated Tubs is another challenge that the Norwegian Logistics Company looks to its S2CT Asset Management System and Watson to keep track of. The Ji'an Seafood Distribution Center executes a Blockchain-of-Custody entry and the Ji'an Logistics Company's driver executes an EV before departing.

⑨ Ji'an Seafood Restaurant

The Ji'an Logistics Company monitors the van's journey and the Cold-Box's operation throughout the 20-minute or so journey to the Ji'an Seafood Restaurant. The delivery van arrives and the driver unloads the chilled caviar cartons and the two Cargo Monitors from the Cold-Box. The Seafood Restaurant's receiving manager visually inspect the chilled caviar cartons. The receiving manager reads the Cargo Monitor data that has been accumulating during the Caviar's journey from the Norwegian Fish Market into the restaurant's Receiving System. ![]() The restaurant's Receiving System quickly correlates the caviar cartons and Cargo Monitors and evaluates the journey's temperature records. Upon satisfactory visual inspection and no temperature alerts from the correlated Cargo Monitor data, the shipment is excepted. A Blockchain-of-Custody is recorded in the Ji'an Seafood Restaurant's Receiving System and is noted in the Ji'an Seafood Distribution Center's Asset Management System. The driver executes an EV, before the delivery van departs the restaurant's receiving area, recording the cargo's successful delivery.

The restaurant's Receiving System quickly correlates the caviar cartons and Cargo Monitors and evaluates the journey's temperature records. Upon satisfactory visual inspection and no temperature alerts from the correlated Cargo Monitor data, the shipment is excepted. A Blockchain-of-Custody is recorded in the Ji'an Seafood Restaurant's Receiving System and is noted in the Ji'an Seafood Distribution Center's Asset Management System. The driver executes an EV, before the delivery van departs the restaurant's receiving area, recording the cargo's successful delivery.

(1) Sub GHz is a bidirectional communications frequency that is best suited for communications in and around Highly Metalized Environments (HME). The actual frequency selection is driven by the reliability of the communications and the power consumed to undertake them. S2CT has developed an "Open Protocol Standard" called HME Sub GHz, 433 MHz for this purpose. Alternatively, the new Sub GHz 900 MHz Wi-Fi 802.11ah IEEE Standard is another good choice and is currently being analyzed by S2CT and Hong Kong City University.